An Introduction to Passive House: Is it right for your project?

We’re excited to announce that our firm is now 100% Passive House Tradesperson Certified (aka… both of us). Recently, both Adam and Abe completed the Emu Passive House Bootcamp. We wanted to share a little about the experience, along with some key takeaways, to help you decide whether pursuing Passive House certification might be right for your project.

First off - what is a Passive House?

Passive House is both a design philosophy and a set of performance standards that a project must meet to achieve certification. At its core, it focuses on creating a highly efficient, well-sealed building envelope that can drastically reduce energy use over time.

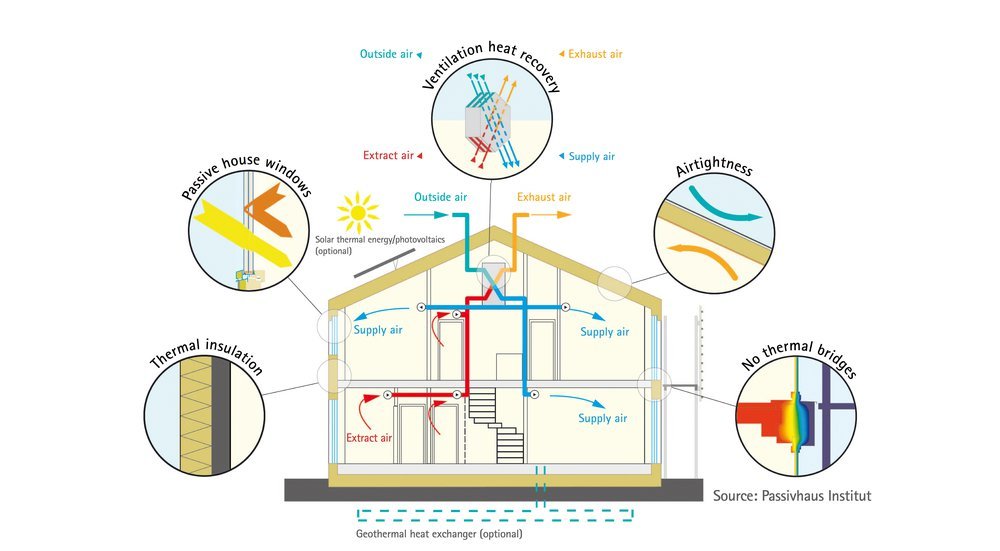

Compared to a standard code-built home, a Passive House can reduce heating energy demand by up to 90%. It accomplishes this by centering design around five core principles:

Entire Envelope Insulation

Wrapping the building in a continuous, fully insulated envelope.Airtight Construction

Minimizing uncontrolled air leakage to prevent drafts and energy loss.Renewed Fresh Air

Continuously supplying fresh, filtered air while recovering heat from exhaust air.Thermal Bridge Mitigation

Limiting points where heat can easily escape through the building structure which also comes with the risk of internal condensation or mold growth.High-Performance Fenestration

Typically triple-pane units that are carefully detailed and thoughtfully located.

Together, these principles create homes that are both energy efficient and comfortable.

Source: Passive House Institute

Climate-specific and flexible

Passive House certification is climate-specific. A Passive House in Denver follows different performance targets than one built in Phoenix or Breckenridge. There are also certification standards tailored specifically for renovations, meaning Passive House principles can be applied across a wide range of project types and scopes.

What does this mean for cost and process?

Designing and building to Passive House standards does require additional time, coordination, and detailing, which can lead to a longer design and construction timeline. Higher-performance materials can also mean higher upfront costs. There are also meaningful cost benefits to Passive House design over time. Because heating and cooling demands are so much lower, HVAC systems can be significantly smaller, simpler, and less expensive to operate. Despite the name, Passive Houses aren’t truly “passive.” Mechanical systems are still required—but by leveraging site advantages and thoughtful detailing, we can greatly reduce their size and complexity.

In some cases, these standards can feel like they introduce aesthetic constraints, but that’s where we come in. Our job as designers is to ensure your project meets certification requirements while still reflecting your unique needs, priorities, and design vision.

Health, comfort, and durability

Passive Houses also prioritize occupant health. Certification requires a continuous ventilation system that constantly circulates fresh, filtered air throughout the home, ensuring excellent indoor air quality. Thanks to the rigorous insulation and airtightness requirements, especially in climates like Denver, Passive Houses also tend to be more sound proof than a typical home.

Why thermal bridges matter (a lot)

Limiting thermal bridges is taken very seriously in Passive House design. A thermal bridge is any interior-to-exterior connection that punctures the insulation layer—think cantilevered beams or tight, hard to reach corners. These details can create clear pathways for heat to escape, undermining the performance of even the most well-insulated envelope.

Just as importantly, thermal bridges can create cold surfaces within the building assembly, increasing the risk of condensation and mold inside the envelope. A key concept in Passive House construction is the placement of the air barrier on the warm side of the insulation. This keeps warm air warm, prevents cold air from coming into contact with warm surfaces, and significantly reduces the potential for moisture-related issues.

As part of the Passive House certification process, thermal bridging is carefully analyzed and quantified to ensure the envelope performs as intended—not just for energy efficiency, but for long-term durability and occupant health. While it’s impossible to eliminate thermal bridging entirely, the goal is to minimize it and confirm that what remains won’t compromise overall building performance.

The analogy used during training was learning to live with the “mice-sized” problems while making sure there are no “elephant-sized” ones. In other words, Passive House doesn’t demand perfection—it demands awareness, analysis, and intentional design decisions that prevent small issues from becoming big, costly ones over time

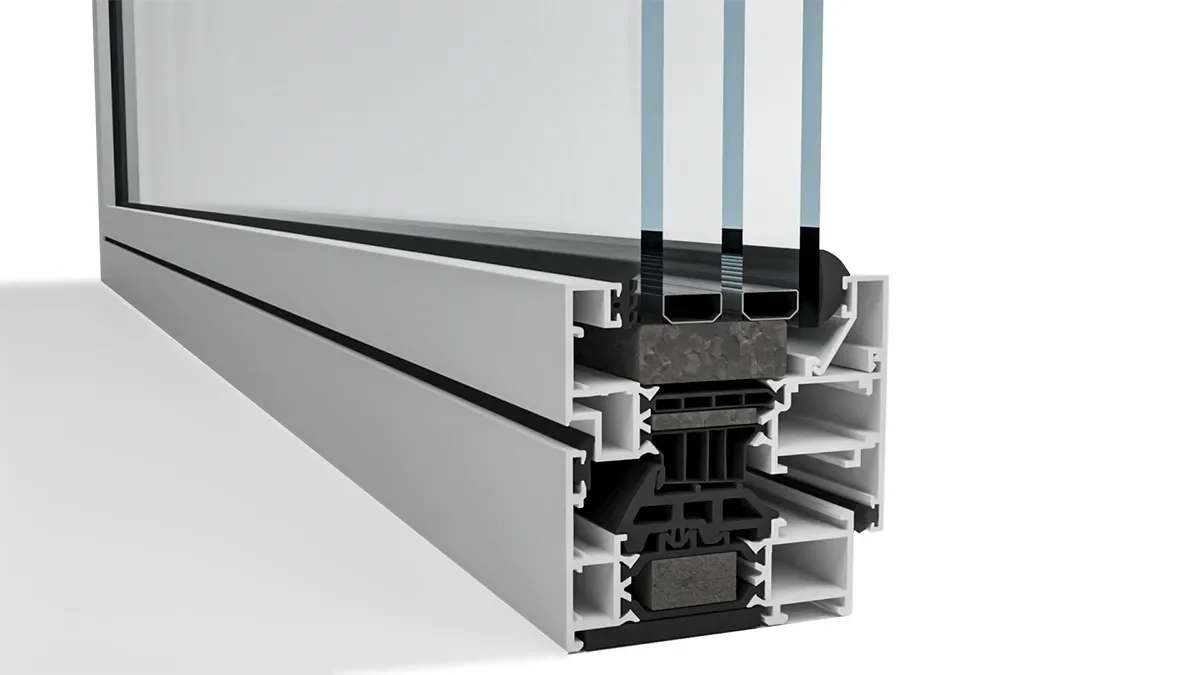

A quick note on windows

Windows are where a large portion of heat transfer occurs, so choosing the right windows is critical. This includes careful consideration of placement, sizing, frame material, and installation details.

And an important note: I said quality, not expensive. Cost and performance are not always directly correlated. In many cases, more expensive windows don’t necessarily perform better. Frame materials and proper flashing details often matter more than price alone.

The big picture

Ultimately, the goal of Passive House is to create longer-lasting, healthier, and more efficient buildings. If this sounds like something you’d like to explore for your project, we’re here to help. Don’t hesitate to reach out with questions, ideas, or curiosity, we’re always happy to talk Passive House.

Schedule a time to talk with us here